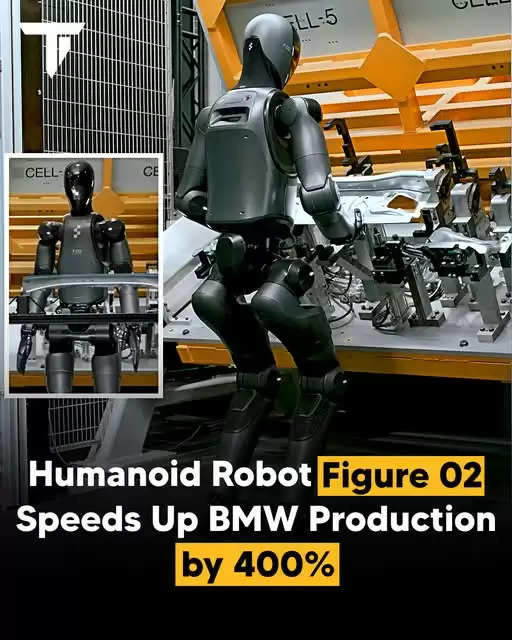

Figure AI and BMW Unveil Major Upgrades to Humanoid Robot for Industrial Use

Excitingly, Figure AI and BMW have just unveiled significant improvements to the Figure 02 humanoid robot, meant to transform industrial activities. Faster, more efficient, and able of tackling more difficult tasks this improved version of the robot has witnessed amazing advancements.

The improved Figure 02 stands out mostly for its amazing 400% speed increase. It not only moves faster but also remarkably seven times better in work performance. This allows the robot to currently complete tasks far more precisely and dependably than it could have years before.

A recent video showing clearly highlighted the capabilities of this improved robot. Showing millimeter-level accuracy, the Figure 02 was demonstrated doing 1,000 placements a day including a delicate chore whereby it put sheet metal into a pin-pole just under one centimetre wide. For sectors like automotive production that call for great accuracy, this degree of precision changes everything.

The Figure 02's speed and efficiency fit a bigger trend towards the increasing application of humanoid robots in factories and other industrial environments. These robots are becoming useful instruments that might assist address labour shortages, save prices, and increase production productivity—not only for display. Figure AI and BMW's collaboration emphasises the part robots are playing in changing the way goods are produced and points to a future in which automation is progressively important to manufacturing.

Some significant IT industry players have supported the creation of Figure AI's humanoid robots. From heavyweights including OpenAI, Nvidia, Microsoft, and Jeff Bezos, the startup recently raised an amazing $675 million in investment. With a current valuation of $2.6 billion, Figure AI is quite on its way to increase its operations and spread additional humanoid robots by 2025.

This partnership with BMW is especially significant since it shows how the automotive behemoth is embracing robotics to keep ahead of the curve in manufacturing. BMW's participation in this initiative also indicates how other sectors can shortly follow suit, implementing like technology to improve their manufacturing lines and increase their flexibility and efficiency.

Looking future, businesses outside of manufacturing could benefit much from the employment of humanoid robots like the Figure 02. These multipurpose task-oriented robots could find application in everything from logistics to healthcare since they are meant to manage a range of chores. Robots may play increasingly advanced roles as the technology develops, performing everything from assembly labour to assisting with more difficult jobs in sectors requiring accuracy and adaptability.

All things considered, the improvements to the Figure 02 humanoid robot offer an interesting window into the direction of automation. This robot is ushering a new age of robotics in the workplace with its faster speeds, greater task completion rates, and amazing accuracy. With ongoing research and development as well as alliances like the one with BMW, humanoid robots may soon be a regular sight in manufacturers and factories all around.

--